air purifier requirement

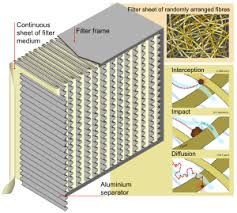

description The requested resource (/aham_cm/site/pages/index.html%3Fcode=r.rac.AboutThisProgram) is not available. Resources > Facts About True HEPA Filtration HEPA is an acronym for "High Efficiency Particulate Air" or "HighThis acronym refers to a filter that is manufactured, tested, certified, and labeled in accordance with current HEPA filter standards. There are several sub-classes within theThe minimum HEPA category requires the filter to capture 99.97% of the 0.3-micron (0.000012-inch) particles in the air passing through The ultra-fine, glass-fiber medium captures microscopic particles that can easily pass through other filters by a combination of diffusion, interceptionTo meet the minimum requirements of a HEPA filter, the filter must be tested and certified to prove that it will remove at least 99.97% (9,997 out of 10,000) of particles 0.3-micron in diameter from the air passing through the filter. Particles that size are about

300 times smaller than the diameter of a human hair, and 25 to 50 times smaller than we can see. To a HEPA filter, catching a one-micron particle (1/1,000,000 of a meter) is the equivalent of stopping a cotton ball withManufacturing a filter with HEPA filter media does not mean that the filter itself meets true HEPA efficiency requirements. filter leakage can go undetected if filters are not individually tested and certified at the end of the manufacturing process. pinhole leaks in the media or breach of the seal between the media pack and the filter frame can compromise the efficiency of the filter and cause it to fall below HEPA standards. Testing the completed filter in accordance with recognized industry standards is the only way to ensure the performance and integrity of that filter. Are HEPA filters suitable for infectious patient isolation?Current CDC Guidelines for Environmental Infection Control in Healthcare Facilities recommend HEPA filtration for the capture of pathogens, microbial

spores and other contaminants in the air exhausted from patient isolation No, quite the contrary. Unlike electrostatically-charged air filters and other technologies that experience substantial loss of efficiency as they become dirty, exactly the opposite typically happens with HEPA filters. The dirtier a HEPA filter gets, the more efficient it can become. Recommended practices for HEPA filter construction, performance, labeling and certification are maintained by the Institute of Environmental Sciences and Technology (IEST) and Underwriters Laboratories (UL). Is in-service efficiency testing also required or recommended? Periodic testing (every 6 to 12 months) and testing whenever the HEPA filter is replaced are essential to ensuring that a HEPA filtration device continues to provide true HEPA efficiency. CDC Guidelines recommend such periodic testing and it is commonly required by facilities as well. It should also be noted

that HEPA filters can begin to break down over time. years is highly recommended, even if the device is not used.

room air conditioner purifier Filter efficiency studies have shown that 0.3-microns is very close to

how to treat mold in air vents what is known as the "Most Penetrating Particle Size (MPPS)" for

wii lens cleaning kit for saleEfficiency is typically greater than 99.97% against larger or smaller particle sizes. Particles larger than 0.3 microns are more easily trapped, or intercepted, by the media. lack sufficient mass to penetrate the media. Most HEPA units have wood or particleboard frame HEPA filters. Why are HEPA-CARE units equipped with metal frame HEPA filters? CDC infection control guidelines recommend replacing wood frame filters in

HVAC systems with metal frame filters due to the potential for microbial contamination that can potentially compromise air quality should the frame become and remainWe do not believe that HEPA filters with wood or fiberboard frames are suitable for critical infection-control applications either. They may be less costly initially, but in addition to microbial contamination wood frames are also far more susceptible to problems such as warping, cracking or distortion. Do Abatement’s HEPA-CARE HEPA filters meet IEST & UL requirements?In fact, our HEPA-CARE Air Purification Systems are actually equipped with high-efficiency HEPA filters that significantly exceed these requirements. These filters are tested and certified to 99.99% HEPA efficiency, which means that they remove at least 99.99% of particles as small 0.3 micronsIn other words, permissible leakage (1 out of 10,000 particles) is 3 times lower than for a standard HEPA filter (3 out of 10,000 particles).

The filters are constructed from microglass media in accordance with the IEST construction requirements and tested and labeled in accordance with IEST safety requirements and UL 900 flammability requirements. Do HEPA-CARE pre-filters offer any added user benefits?Cellulose-based filter media can become a fertile breeding groundOur MERV 8 pre-filters are treated with an EPA registered, broad-spectrum anti-microbial designed to inhibit microbial growth and protect the integrity of the filter media. The size and concentration of airborne contaminants, temperature, humidity conditions and duration of use determine how often filters need replacement. As all air filters become loaded with particulate matter, the static pressure differential across the filters will increase, and the airflow capacity of the air filtration device will decrease. To make operation simple, Abatement HEPA-CARE Air Purification Systems are equipped with separate,